■G-Brane *TIPS PVDF ■PES ■*NIPS PVDF

* TIPS : Thermal Induced Phase Separation

* NIPS : Non-Solvent Induced Phase Separation

* PVDF : Polyvinylidene Fluoride

| ITEM | G-Brane P5 | G-Brane P7 | G-Brane S2 | G-Brane S3 | G-Brane S4 | ||

|---|---|---|---|---|---|---|---|

| Module | Model | GB-MHPV05A | GB-MHPV07A | GB-MHSV02A | GB-MHSV03A | GB-MHSV04A | |

| Effective Area | 50m2 | 75m2 | 29m2 | 35m2 | 40m2 | ||

| Dimension | Ø216x 1,732mm | Ø216x 2,152mm | Ø234x 1,653mm | Ø234x 1,968mm | Ø234x 2,264mm | ||

| Material | ABS, PU | ||||||

| Type | Pressurized | Submerged | |||||

| Operation Condition | Flux | 40 ~150LMH | 15 ~ 65 LMH | ||||

| Pressure | < 3kgf/cm2 | < 0.47 kgf/cm2 | |||||

| Temperature | < 40°C | ||||||

| pH | 1 ~ 12 | ||||||

| Weight | Dry | 24kg | 30kg | 16kg | 20kg | 24kg | |

| Wet | 40kg | 46kg | 36kg | 40kg | 44kg | ||

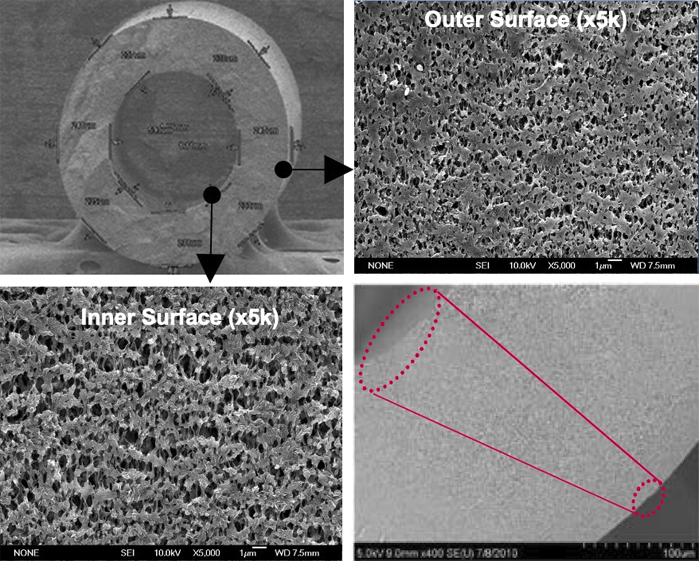

| Membrane | Material | PVDF (Polyvinylidene Fluoride) | |||||

| Type | Hollow Fiber | ||||||

| Pore Size | 0.1μm | ||||||

| Flow Configuration | Outside-In | ||||||

| Max. NaOCl Conc. | 5,000 mg/L | ||||||

| Model | Facility | Capacity | Year |

|---|---|---|---|

| G-Brane P Series | LCD Industrial Complex UPW Pre-Treatment | 334,000m3/day | 2013 ~ 2021 |

| LCD Industrial Complex Reuse of Wastewater | 25,000m3/day | 2013 ~ 2019 | |

| P Company Seawater Desalination Pre-Treatment Facility | 67,000m3/day | 2021 | |

| L Company Chemical UPW Pre-Treatment | 16,000m3/day | 2015 ~ 2017 | |

| China Deqing City Reuse of Sewage | 10,000m3/day | 2017 | |

| G-Brane S Series | LCD Industrial Complex Reuse of Wastewater | 50,000m3/day | 2013 ~ 2019 |

| Gumi City Reuse of Sewage | 8,600m3/day | 2018 | |

| K Institution Seawater Desalination Pre-Treatment | 1,200m3/day | 2017 | |

| China Jiangxi Reuse of Wastewater | 500m3/day | 2018 | |

| JG Pears Reuse of Wastewater | 360m3/day | 2018 | |

| S Company Wastewater Treatment | 200m3/day | 2021 |

- Many other references

Outside-In

•Physical cleaning methods such as air-scrubbing is possiblemb

•Suitable for large-scale water purification treatment

Inside -Out

• An effective membrane fouling control through the high ShearStress caused by fast flow rate

•Suitable for concentration / purification of highly condensed water

| ITEM | Hisep | |||

|---|---|---|---|---|

| Module | Model | HUF3050 | HUF8050 | |

| Effective Area | 5.21m2 / *9.51m2 | 21.77m2 / *39.71m2 | ||

| Dimension | Ø89x 1,342mm | Ø242x 1,575mm | ||

| Material | PVC,EPOXY | UPVC,EPOXY | ||

| Type | Pressurized | |||

| Flux | 21 ~60LMH | |||

| Pressure | 1kgf/cm2 | |||

| Temperature | 35°C | |||

| pH | 3 ~11 | |||

| Weight | Dry | 3.4kg | 15kg | |

| Wet | 5.5kg | 30kg | ||

| Membrane | Material | PAN(Polyacrylonitrile) | ||

| Type | HollowFiber | |||

| MWCO | 30k ~300k Dalton | |||

| Flow Configuration | Inside-Out/ Outside-In | |||

| Max. NaOCl Conc. | 500mg/L | |||

* Outside-In

| Facility | Capacity | Model | Year |

|---|---|---|---|

| W.Jeju City Reuse of Sewagewater | 3,600m3/day | Hisep 8050 | 2015 |

| E.Jeju City Reuse of Sewagewater | 1,800m3/day | Hisep 8050 | 2021 |

| K Island Seawater Desalination Pre-Treatment | 720m3/day | Hisep 8050 | 2009 |

| H Company Reuse of Wastewater | 400m3/day | Hisep 8050 | 2019 |

| P Company Oil-Waste Treatment | 20m3/day | Hisep 3050 | 2010 |

| M Company Acetic Acid Concentrate | 10m3/day | Hisep 3050 | 2020 |

- Many other references

| Applied Field | Contents |

|---|---|

| Oxygen generator | • Aerobic microorganism culture |

| • Medical and general air conditioning equipment | |

| • Waste treatment by smelting and incineration | |

| Nitrogen generator | • Exhaust and inert gas filling of chemical process tanks and containers |

| • Filling containers for food production processes and packaging | |

| • Heat treatment of metals | |

| Dehumidifier | • Remove moisture from the air |

| • Dehydration of gas mixture | |

| Biogas purification | • Reduction of carbon dioxide in the air |

| • Separation of methane and carbon dioxide in gas mixture |

| ITEM | Gas Separation | ||

|---|---|---|---|

| Model | PFN | PFO | |

| Target Gas | Nitrogen | Oxygen | |

| Filtration Type | Solution~Diffusion | ||

| Module | Effective Area | 1~ 40m2 | |

| Diameter | 55~200mm | ||

| Length | 200~1,500mm | ||

| Material | Nylon,PVC, Aluminum, STS | ||

| Type | Pressurized | ||

| Flux (*GPU) | 10~40GPU | ||

| Pressure | 1~12kgf/m2 | ||

| Temperature | <40°C | ||

| Membrane | Material | PSf(Polysulfone), PES | |

| Type | Hollow Fiber | ||

| Facility | Target Gas | Purity | Flow Rate | Year |

|---|---|---|---|---|

| S Company Air Purifier | O₂ | 30%> | 2LPM | 2011~ 2020 |

| M Casting Factory Contact Membrane | Dissolved Oxygen | 50ppm | 8.3LPM | 2014,2020 |

| S Company Dehumidifier Membrane | Dehydration | 5%< | 80LPM | 2018 ~ 2020 |

| S Company IPA Concentrate | IPA | 30%> | 600L/day | 2020 |

| H Laboratory Nitrous Oxide Separation | N₂O | 40(선택도) | 100GPU | 2017 |

- Many other references